Keeping Cool Beyond OSHA

The Occupational Safety and Health Administration (OSHA) can trace its history back to President Nixon’s signature in 1970. Driven by calls from labor unions and the increasing reality of deaths and disabilities in many industries, both OSHA and its sidekick NIOSH were born. Interestingly, OSHA became a division of the Department of Labor while NIOSH (National Institute for Occupational Safety and Health) reported into the CDC, alias Health and Human Services. Clearly the former deals with enforcement and the latter with research.

Since its inception OSHA has done much to improve industrial safety, often in response to tragic episodes. Many efforts and compliance directives have focused on chemicals and pollutants such as asbestos, vinyl chloride, arsenic, lead, benzene, and carcinogens. Unsafe working conditions have been eliminated or diminished in many industries including shipbuilding, meat packing, petroleum refining, sugar, grain, construction, textile, and process industries.

While such regulations have dealt appropriately with obvious industrial issues, it was not until 1987 that minimal initial standards were issued for the more subtle, seasonal, and variable issue of Heat Stress. This originated in the fields where low wage braceros roamed from crop to crop to harvest our nation’s agricultural bounty. These invisible and defenseless Mexicans would perform the “Stoop Labor” that was somehow a better living standard than in their own country. The basic regulations demanding potable drinking water, toilet type facilities, and clean water for washing hands was an initial step and those instructions are still posted in most restaurant bathrooms to this day for kitchen help.

Now let’s fast forward to the Heat Stress Issues of today:

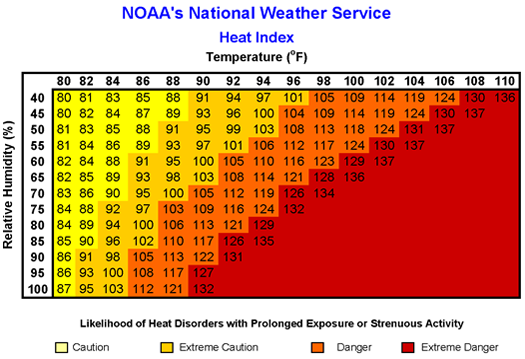

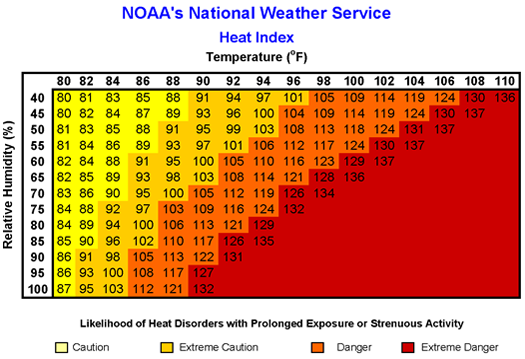

As you can see, the combined impact of heat and humidity greatly increases as each one increases.

As you can see, the combined impact of heat and humidity greatly increases as each one increases.

In less humid areas (40 % or less) a simple 180 psi booster pump can suffice with a significant cost savings if no more than 25 nozzles are required for cooling 4-5 workers in auto shops and related venues.

In summary, because the impact of Heat Stress varies with the worker exertion level, humidity, and shade factors it is clearly up to management to determine the best path to reduce the chance of incidents and consider the improved performance of workers by providing a cooler atmosphere.

In less humid areas (40 % or less) a simple 180 psi booster pump can suffice with a significant cost savings if no more than 25 nozzles are required for cooling 4-5 workers in auto shops and related venues.

In summary, because the impact of Heat Stress varies with the worker exertion level, humidity, and shade factors it is clearly up to management to determine the best path to reduce the chance of incidents and consider the improved performance of workers by providing a cooler atmosphere.

- Many companies still look at resolving Heat Stress as a business cost and not an opportunity.

- Heat Stress is addressed by “Definitions, Symptoms, and Guidelines”.

- Manufacturing operations and distribution budgets are always under intense scrutiny, often by management in air conditioned offices not even on job locations.

- Much of the OSHA standards, by necessity, deal with modifying work schedules where possible, emergency planning, supervisor training, and promoting adequate water and rest breaks.

As you can see, the combined impact of heat and humidity greatly increases as each one increases.

As you can see, the combined impact of heat and humidity greatly increases as each one increases.

- At 40% humidity and 88 degrees the index is only 88

- At 40% humidity and 94 degrees the index is up to 97

- At 40% humidity and 100 degrees the index is now 109

- At 60% humidity and 88 degrees the index is up to 95

- At 60% humidity and 94 degrees the index is up to 110

- At 60% humidity and 100 degrees the index is now 129

In less humid areas (40 % or less) a simple 180 psi booster pump can suffice with a significant cost savings if no more than 25 nozzles are required for cooling 4-5 workers in auto shops and related venues.

In summary, because the impact of Heat Stress varies with the worker exertion level, humidity, and shade factors it is clearly up to management to determine the best path to reduce the chance of incidents and consider the improved performance of workers by providing a cooler atmosphere.

In less humid areas (40 % or less) a simple 180 psi booster pump can suffice with a significant cost savings if no more than 25 nozzles are required for cooling 4-5 workers in auto shops and related venues.

In summary, because the impact of Heat Stress varies with the worker exertion level, humidity, and shade factors it is clearly up to management to determine the best path to reduce the chance of incidents and consider the improved performance of workers by providing a cooler atmosphere.